ProtoTRAK® XYZ

Maximum control

Minimum complexity

ProtoTRAK CNC control combines user-friendliness with powerful features such as TRAKing®, simulation, manual mode, and a modular structure. Perfect for prototyping, one-offs, and small batch production.

Request a demo

Easy operation

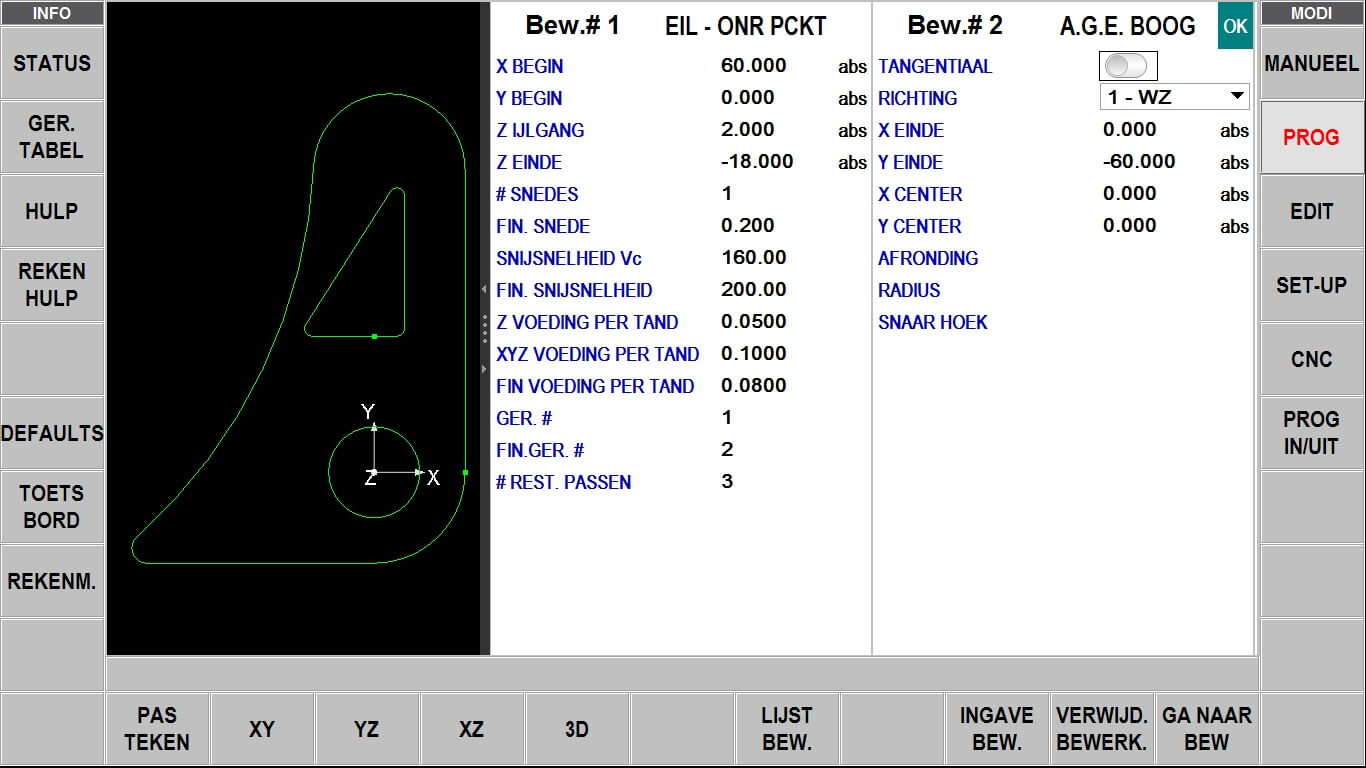

The goal of ProtoTRAK is to get you machining as quickly as possible. No hassle with G-codes or complex dialogues. With ProtoTRAK, you can effortlessly turn or mill workpieces without programming knowledge! ProtoTRAK is designed to be user-friendly, making it accessible to operators of various experience levels.

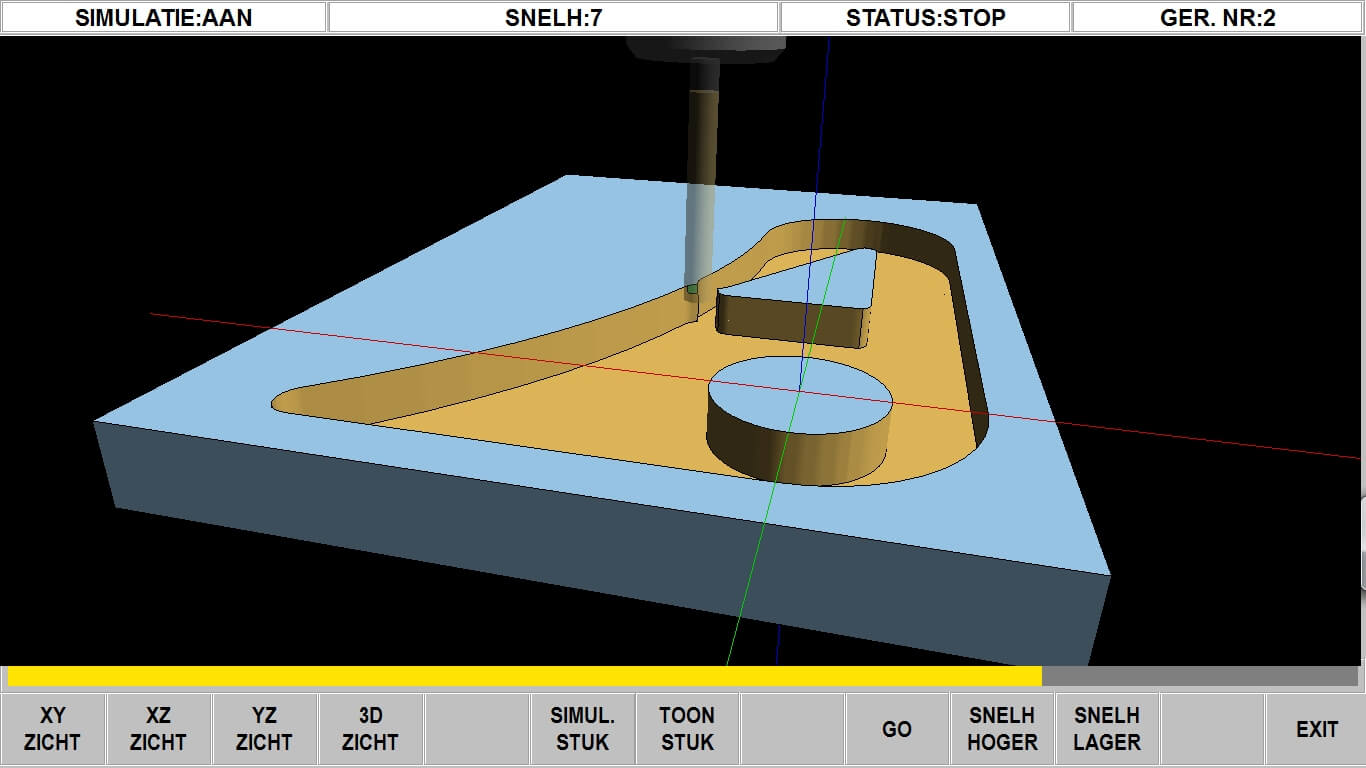

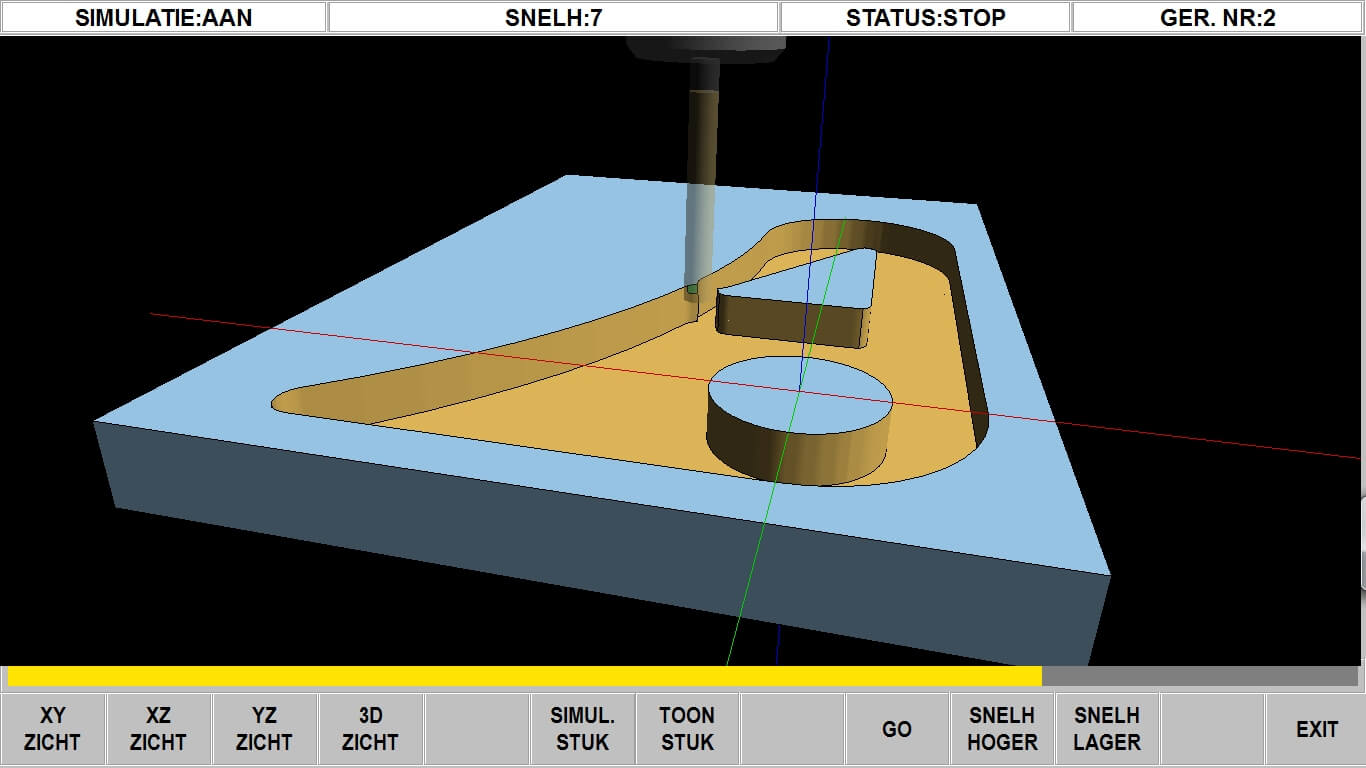

Simulation

After designing the workpiece, the ability to see how a workpiece will look with the available tools. This gives a detailed view of the workpiece before you have actually turned it. Through simulation, you can check for yourself whether the desired result is achieved.

TRAKing

Before pressing start, you can activate TRAKing and gain complete control over the CNC operation. The handwheels follow the program and move at the speed at which you turn the handwheel. This allows you to always stop or even reverse when necessary. With this feature, you have complete control. When you're satisfied, press start to finish the workpiece completely with CNC.

The ProtoTRAK® control

The ProtoTRAK control is designed to optimize the machining process and increase productivity. Thanks to the intuitive interface and conversation-oriented programming language, this control is ideal for both novice and experienced operators. No knowledge of G-code or CAD software is required — ProtoTRAK simply asks the right questions, and you enter the data. This makes programming CNC machines easier than ever.

Not convinced yet?

See below for an overview of all unique features of ProtoTRAK

1

Versatile for both manual and CNC use

ProtoTRAK machines are perfectly suited for a wide range of machining tasks. Operators can effortlessly switch between manual and CNC mode, depending on the task. Thanks to this flexibility, ProtoTRAK machines are particularly popular with small to medium-sized companies that need quick turnaround times and multifunctional use.

2

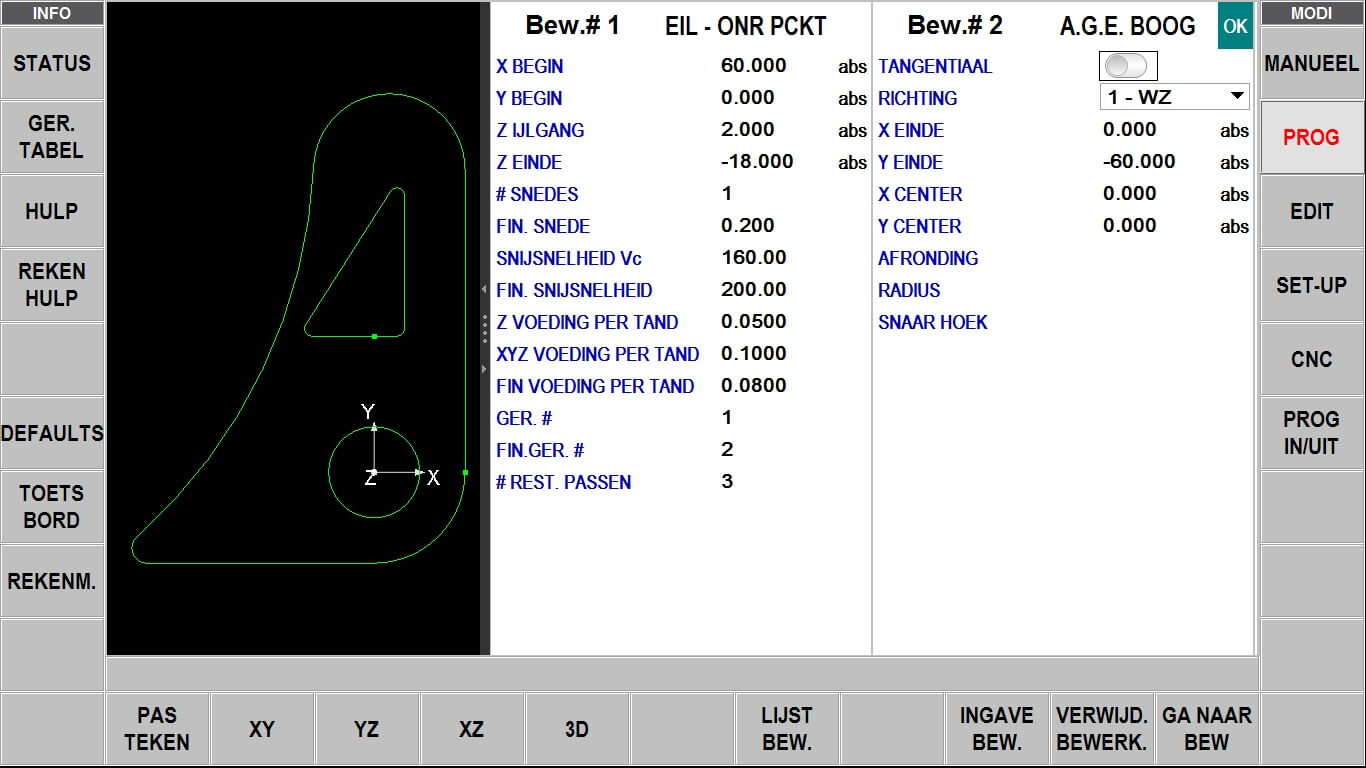

Conversation-driven programming

Instead of complex codes, ProtoTRAK works with a question-and-answer structure. As you enter or indicate dimensions on the screen, the system automatically builds the operation. This makes designing and setting up a workpiece quick, efficient, and accessible

3

Simulation prevent surprises in advance

ProtoTRAK offers a powerful simulation function that allows you to visualize the machining process before execution. This feature shows in detail what the end result will look like, including tool paths. No time? You can skip the simulation and start turning directly

4

TRAKing® unique manual control

TRAKing® is the favorite feature of ProtoTRAK users. By activating this function before CNC start, you get full control over the handwheels. The axes follow the programmed path, but move at the speed of your hand. This allows you to stop, pause, or even reverse when necessary. Only when you are completely sure, you press Start to automatically complete the CNC operation.

5

CNC machining with optimal safety

During CNC operations, the protective cover must be fully closed. This protects the user from chips and other risks, and ensures that the cooling functions optimally. The waterproof shield contributes to the lifespan of your tools and increases process safety.

6

Modular system & parts service up to 25 years

Did you know that ProtoTRAK works with modularly built components? Electronic and mechanical components are often interchangeable between models, which simplifies maintenance and service. ProtoTRAK offers parts service for up to 25 years after purchase — and in many cases, even 40 year old machines can still be repaired

Would you like to experience how easy CNC programming can be?

Request a no-obligation demo

Would you like to experience how easy CNC programming can be? Visit our showroom in Veghel for a no-obligation demonstration of the ProtoTRAK control. Our experts will show you how to program a workpiece in just a few minutes without G-code or CAD software.

Fill out the form below to make an appointment. We will then contact you as soon as possible to schedule a suitable date and time for your personal demonstration.

Meet

ProtoTRAK

ProtoTrak CNC Milling Machines

The ProtoTRAK® CNC/manual control is the best technological solution for small batch machining operations available today. With an XYZ milling machine, you can program components in just a few minutes! And if drawings are made with CAD, you simply use the built-in 'DXF File Converter'. This way, you don't have to worry about programming! The programming time with an XYZ machine is only 3 minutes!

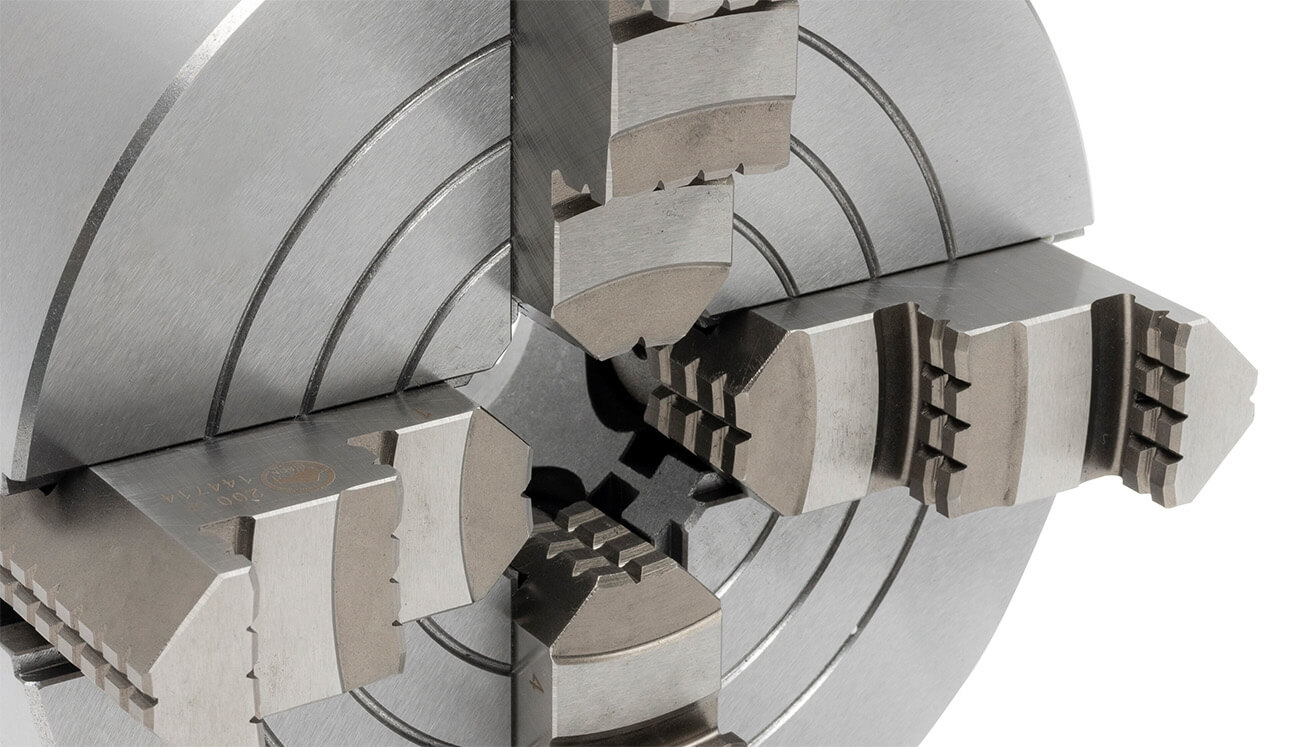

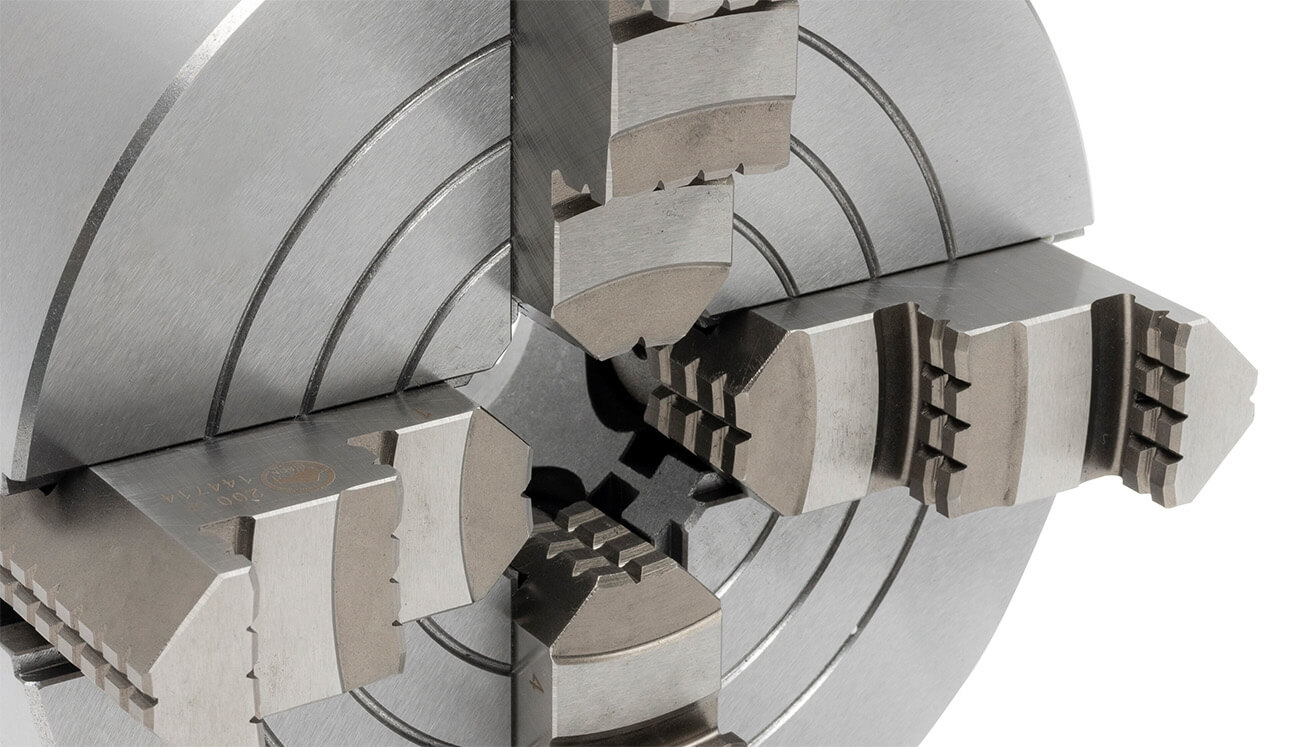

ProtoTrak CNC Lathes

Lathes with less waste and short production time. Experience has shown that the TRAKing function of the ProtoTRAK contributes to less waste, saves tools, and shortens production time! This feature comes standard on the lathes of the RLX series, the lathes in Huvema's range. With the unique TRAKing function, you can slowly roll out a set program step by step using a handwheel.

ProtoTrak CNC Machining Centers

The same RMX ProtoTRAK® control that we offer on our bed mills is now available on a closed unit with all the capabilities of a bed mill. These machines are ideal as a tooling center for machining, while providing optimal safety with the fully enclosed shield, keeping chips and coolant within the machining environment

Fields with a * are required.