1

Oil for the gearboxes

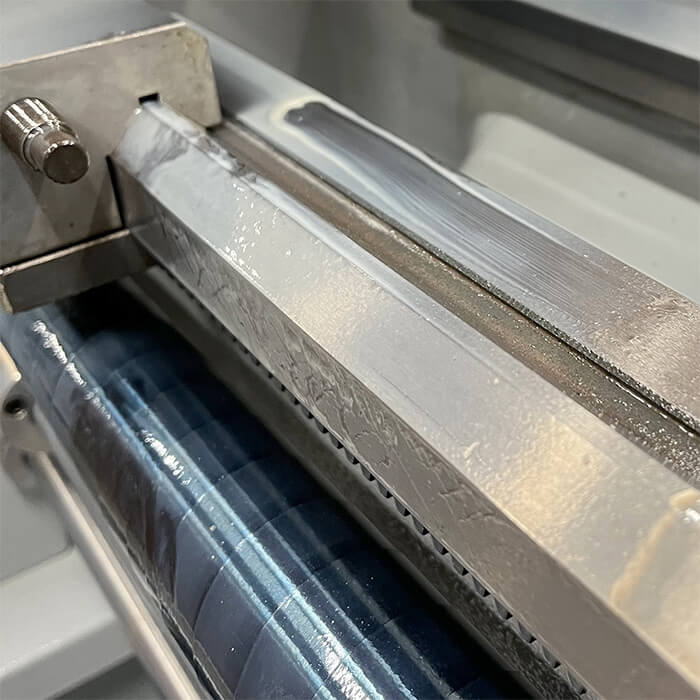

With the oils for the gearboxes, we are talking about the oil for in the norton case, fixed head and lock case.

It contains various gears, which must be kept well lubricated. The gears in the norton box take care of the feeders and threading, for instance lock case is for operating the feeders and threading.

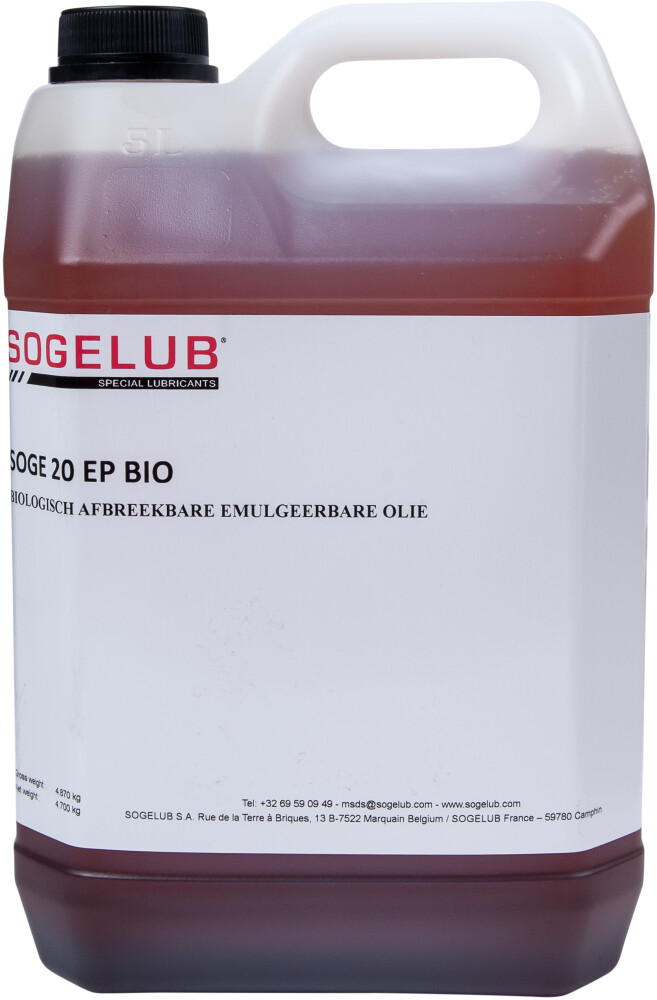

To maintain the gears in these gearboxes, our mechanics always use hydraulic 46 oil.