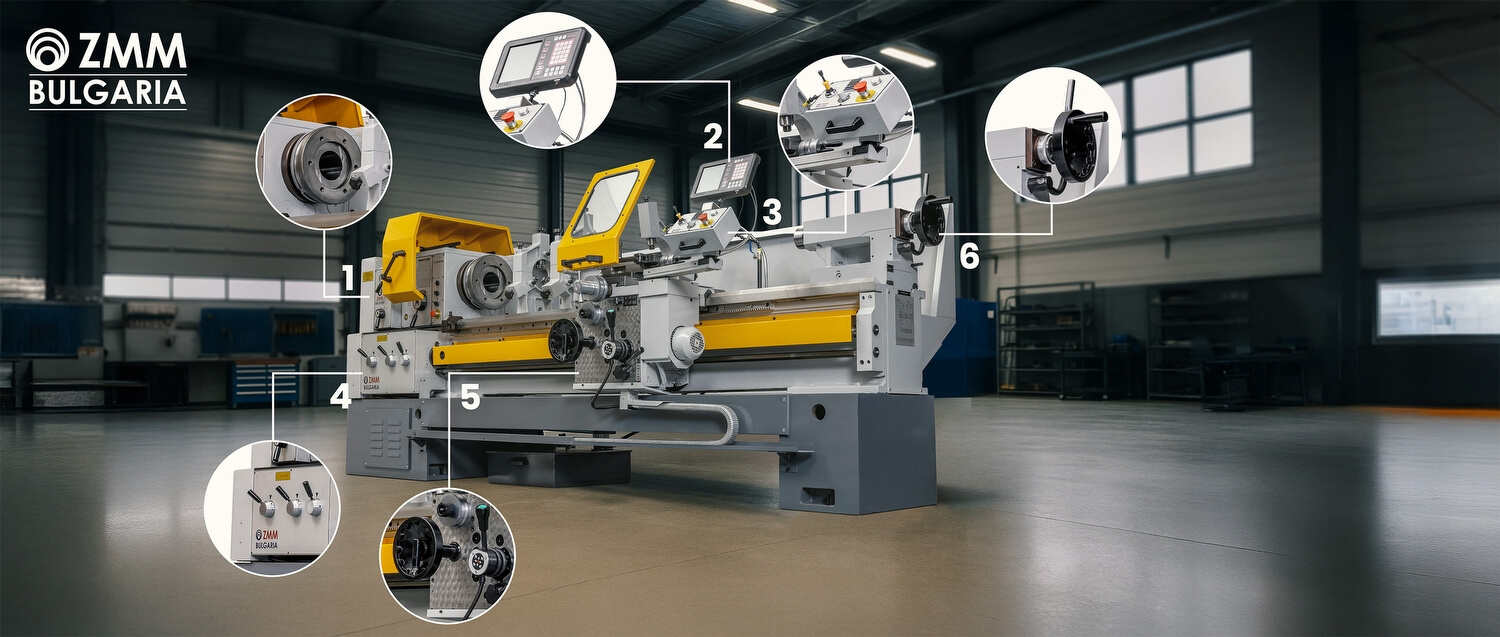

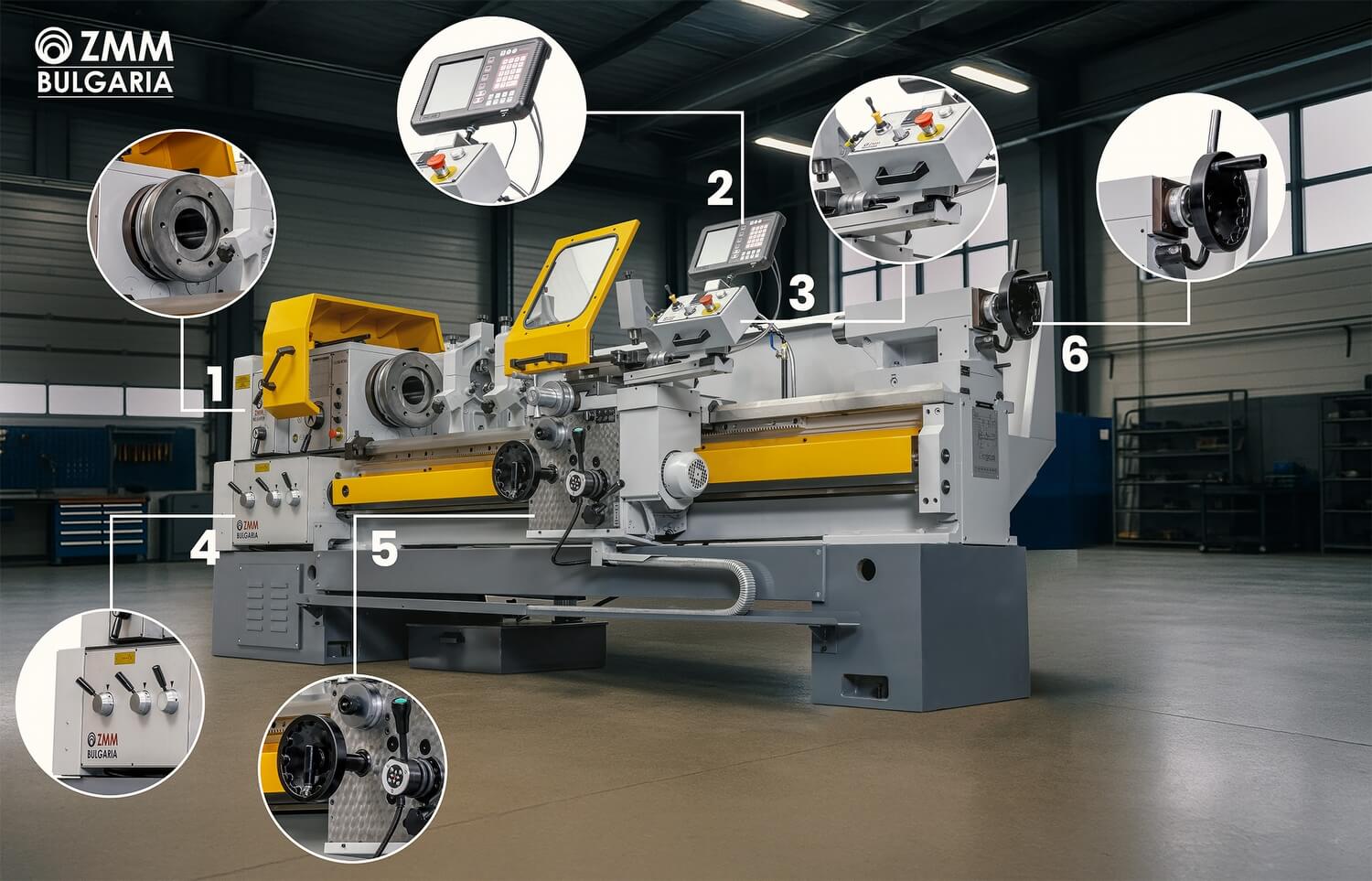

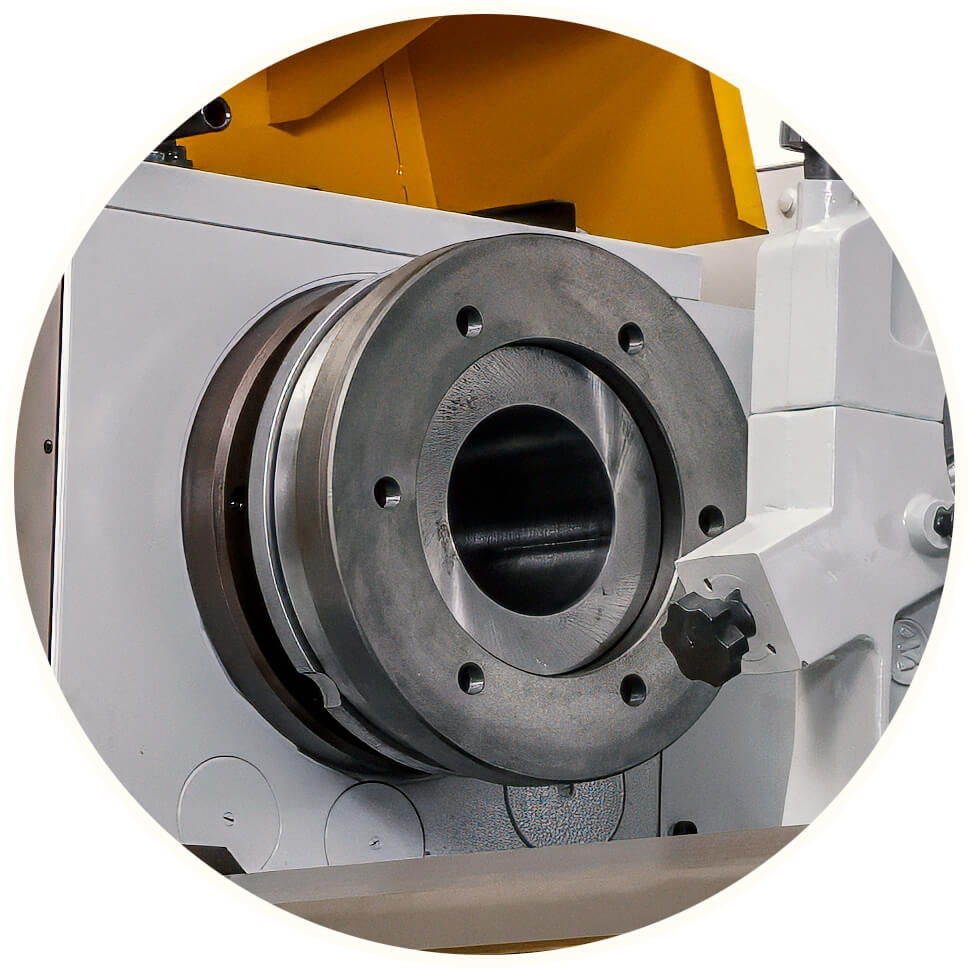

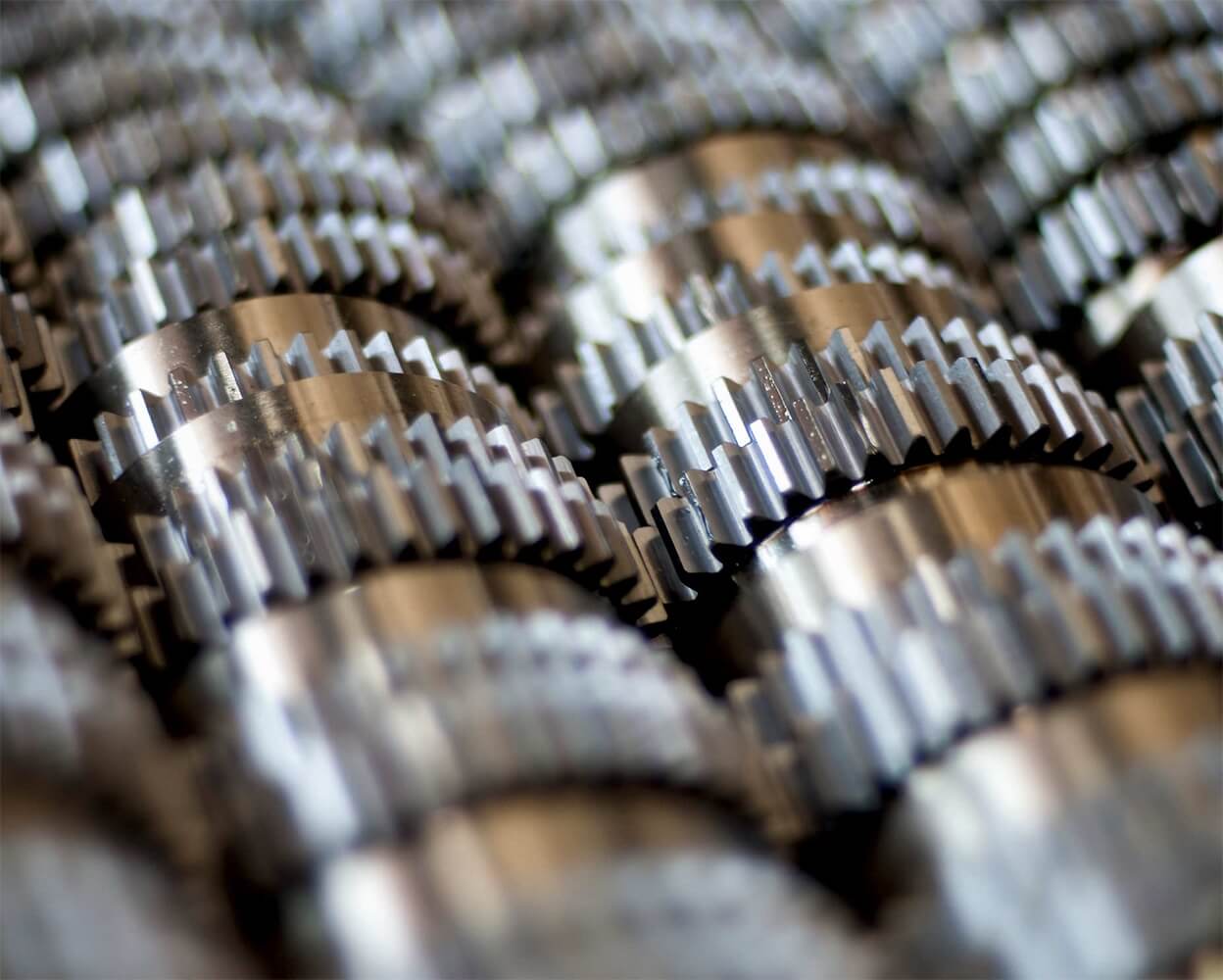

The gearbox features high-quality spindle bearings and robust gears made of induction-hardened carbon steel. The gears and bearings rotate in an oil bath and are additionally lubricated where necessary with an oil pump for maximum durability. The hardened and precision ground spindle rotates smoothly and vibration-free. As standard, the machine is fitted with a DIN 55027 Bayonet connection. Optional Camlock (DIN 55029) or ASA (DIN 55026) fittings are available.

The Newall NMS800 digital readout offers fast and high-precision positioning to 0.01 mm accuracy. Thanks to its robust, dust- and waterproof ruler and encoder (IP67), this readout is perfect for harsh industrial environments. Additional functions such as programming multiple tool offset sets make working with the lathe easier and more efficient.

The ZMM variable-speed lathes are equipped with a Schneider variable speed drive that precisely adjusts the motor speed precisely adjusts the motor speed. This ensures fast upshifting, controlled braking and lower heat generation, which protects the motor and increases productivity. Moreover, you less shifting and the machine does not use a clutch. The result? More efficient work, less wear and maintenance, instant torque and stable performance, even in intensive and prolonged use. You effortlessly adjust direction of rotation and speed via the centrally located control panel on the support.

The feed case offers a wide range of feed rates and thread sizes such as metric, inch, modul and DP (diametral pitch). The clear control panel makes operation simple and efficient.

The machine is equipped with mechanical power supply on the x and y axis and built-in overload protection to prevent damage. In addition, the machine has Ijlgang function on the support for fast movement.

The loose head is easy to move along the bed rails and can even be mechanically or electrically adjustable. For extra versatility, the spindle in the loose head can be equipped with a switchable transmission (1:1 or 1:4). With a lever, you choose between direct drive or a delayed transmission, depending on the operation. This offers more control and power, for example when drilling or tapping large diameters.

The lathes can optionally be expanded with various useful options

For example, the machine bed can be fitted with a removable bag, allowing even extra-large workpieces to be easily machined be easily machined. In addition, it is possible to replace the spindle intake with a camlock system and additional safety features, such as a foot pendulum emergency stop, can be added. Below is an overview of some extensions/modifications.

Removable pocket in the bed (for larger workpieces).

Camlock or ASA spindle attachment.

Thread clock (metric or inch).

Longitudinal stop.

Taper turning attachment.

Foot pendulum with stop.

T-slots on cross slide.

Switchable transmission for loose head (1:1 or 1:4).

Quick-change chisel holder.

ZMM Lathes: Reliable, durable lathes from Europe

Discover ZMM's universal variable-speed lathes. Designed for maximum flexibility, reliability and precision. Thanks to variable speed, these machines offer the perfect balance between control and power.

Why choose a ZMM lathe?

ZMM Bulgaria has been a leading manufacturer of universal and CNC lathes for over 70 years. With annual production averaging 700 machines and customers in more than 80 countries, ZMM is known for its durable and reliable machines. Whether you operate in a workshop, a medium-sized company or heavy industry, ZMM supplies lathes that seamlessly fit your working conditions. All machines are manufactured in Europe, comply with the strictest CE standards and ZMM operates according to the quality management system EN ISO 9001. Thanks to European production, we can deliver a number of models directly from stock or with a short delivery time.

Robust machines with an eye for quality and precision

Each ZMM lathe is constructed of grey cast iron from a single casting (monolithic) and features reinforcement ribs that minimise vibrations and maximise maximise stability. This ensures accurate machining and extends the life of the machine. All components are subjected to strict quality controls. In addition, only high-quality bearings are used, ensuring smooth operation and constant precision, even in long-term use. Before delivery, all lathes are extensively tested and provided with an inspection report according to DIN 8607.

A solution for every application

ZMM offers different types of lathes tailored to specific applications and industries:

Universal lathes: Reliable machines with a turning diameter of up to 1,410 mm and a maximum length of up to 10 metres between centres. Available with variable or switched speeds. User-friendly, versatile and affordable.

CNC lathes: For serial and complex turning work. Equipped with controllers from FANUC, SIEMENS, HEIDENHAIN or FAGOR. For workpieces up to 1,320 mm in diameter.

Oil & country Lathes: Especially for the oil and gas industry. Extra robust, with stainless steel components, two 3-jaw chucks, cone device and suitable for various thread types (metric, inch, module, DP).

Top-quality lathes made in Europe

From casting process to final inspection, ZMM keeps every part of production in-house. All machines are built in Europe and are CE-compliant. ZMM not only produces the machines entirely in Europe, but also uses components from reputable suppliers, which ensures reliability, safety and long service life.

Huvema & ZMM: a strong partnership for over 30 years

For over 30 years, Huvema has been the official Dutch supplier of ZMM lathes. This long-term cooperation guarantees fast delivery, expert support and reliable service.

Ask for a no-obligation demo

Our experienced service engineers work closely with ZMM and are fully familiar with each machine, from installation to maintenance and repair.Schedule an appointment to view ZMM quality in the HUVEMA showroom.

Fill in the form below to make an appointment. We will then contact you as soon as possible to schedule a convenient date and time schedule for your personal demonstration.

Fields with a * are required.