Morse taper, clamping with conventional drilling,

this is how it's done!

In the field of drilling, we still sometimes get questions regarding the holder. Which holder do I need? My holder runs conical with an internal piece of thread at the end, which one is it? I have an old machine, is it still the same? You can't mill with such a ''tab'', can you? We would like to give you some explanations to get you started with recordings for conventional drilling and milling!

Tool clamping with a conventional drill

For conventional drilling machines, we use the Morse taper feed. This guarantees reliable clamping and also allows quick tool changes. The Morse Taper is also often described using the abbreviations MK (Morse Taper), MC (Morse Taper) or MT (Morse Taper). A Morse Taper is used to clamp machining tools (such as spiral drills, drill chucks and reamers) in, for example, (industrial) table and column drills and lathes. The size of the taper shank corresponds to the matching toolholder.

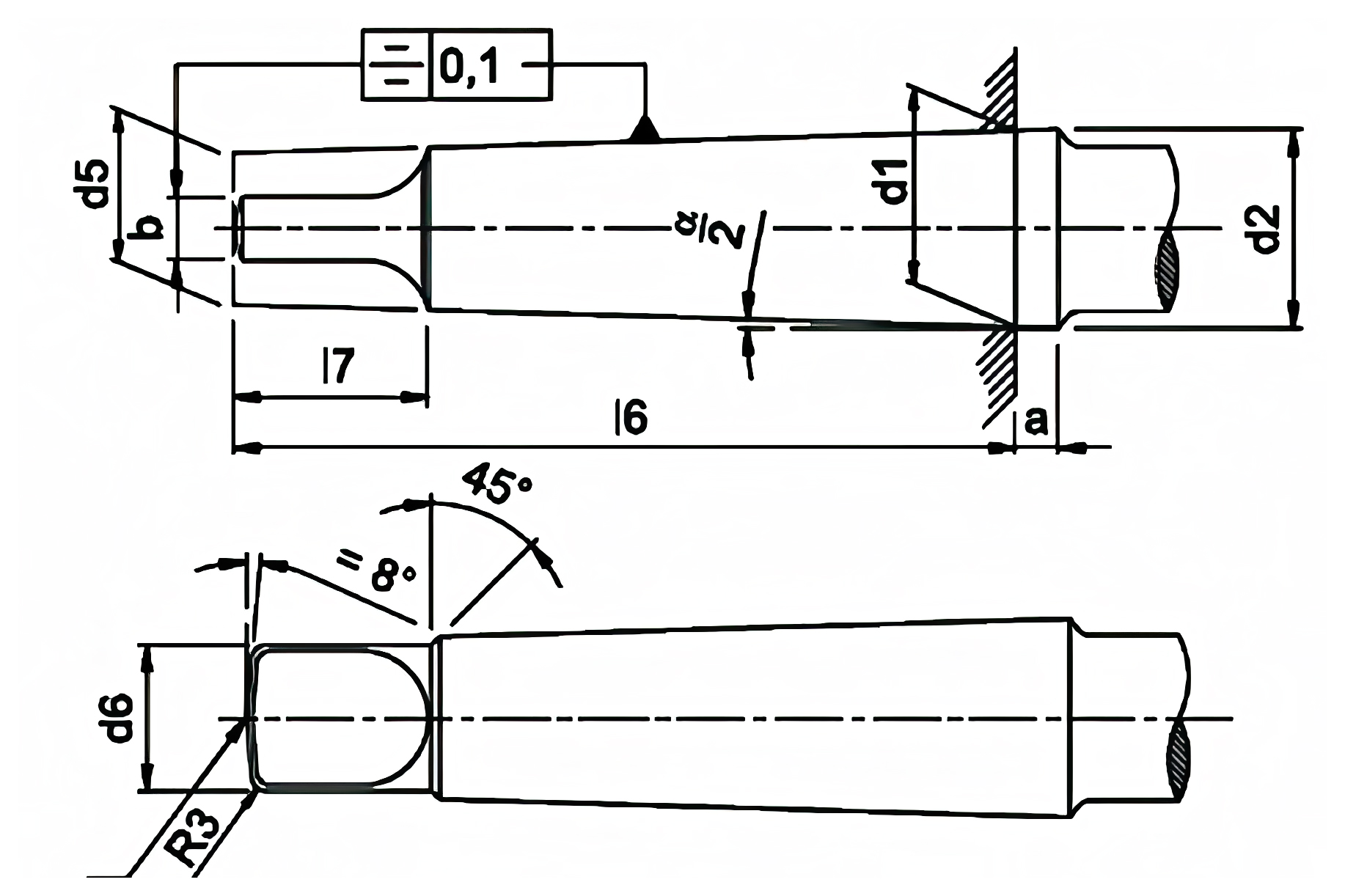

A Morse Taper can be recognised by a slightly conical shaped shaft. The Morse Taper is a standardised tool holder according to DIN 228.

The Morse Taper comes in two forms, type A and type B.

Type A can be recognised by a piece of internal thread at the end of the cone, which is used exclusively with drill bits or milling machines with a threaded rod::

Type B you recognise by a 'tab' (extrusion lip) at the end. This allows you to easily 'tap' the tool out of the machine using an extraction key. This allows you to quickly change tools. Type B is the most common holder for conventional drilling and is used in table and column drills:

Morse Conus holders available in 7 different sizes

Of these, Morse Conus with size 2,3 & 4 are by far the most commonly used sizes for drilling. Here's an overview of the sizes:

| MK0 | MK1 | MK2 | MK3 | MK4 | MK5 | MK6 | |

|---|---|---|---|---|---|---|---|

| a | 3 | 3.5 | 5 | 5 | 6.5 | 6.5 | 8 |

| b | 3.9 | 0.2 | 6.3 | 7.9 | 11.9 | 15.9 | 19 |

| d1 | 9.045 | 12.065 | 17.78 | 23.825 | 31.267 | 44.399 | 63.348 |

| d2 | 9.2 | 12.2 | 18 | 24.1 | 31.6 | 44.7 | 63.8 |

| d5 | 6.1 | 9 | 14 | 19.1 | 25.2 | 36.5 | 52.4 |

| d6 | 6 | 8.7 | 13.5 | 18.5 | 24.5 | 35 | 51 |

| l6 | 56.5 | 62 | 75 | 94 | 117.5 | 149.5 | 210 |

| i7 | 10.5 | 13.5 | 16 | 20 | 24 | 29 | 40 |